I’ve slacked off just a bit, but I’ve still been making some progress. Mostly nothing worth photographing, but today there is. I’ve finished the front of the trailer, down to the floor and less the wiring. Here’s looking from the kitchen to the living room.

Here’s what you see when you step in through the front door.

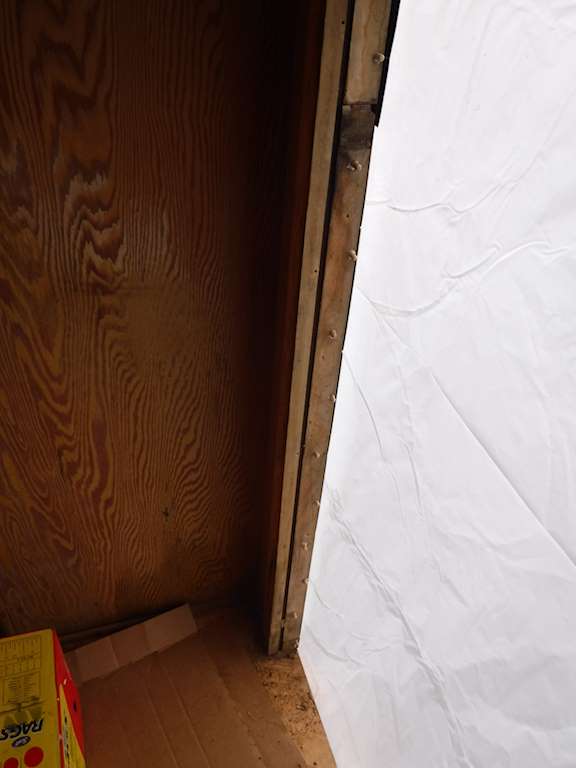

And from the living room looking right toward the front door.

And from the living room looking toward the kitchen. Yes, the kitchen is currently full of stuff. Every flat surface has something on it. I don’t have many work surfaces.

I continue to play with veneer. The cabinet in the living room is mostly covered with veneer, except the drawers. I did this on top:

I also put those door retainers, front and rear. The ones I bought don’t work properly. I had to trim the clip part of them.

Note that the left and right sides are different in that last picture.

Note that the left and right sides are different in that last picture.

I started to put on the external corner moldings, where the vertical walls meet horizontal roof/end. But the molding is pretty marginal in size. It’s about .9 wide by a scant half inch tall. I’m going to buy some a bit larger. I found some that’s an inch and an eight by 5/8 inch that I think will do better. So I have to leave that for a few days. I think I’ll continue on the interior. Probably do the bathroom to the point where I can construct the bed.

And now they look like this:

And now they look like this:

The warm color for the frame and dark stain for the doors and drawer fronts was the original, although none of the original can be used without stripping and re-staining.

The warm color for the frame and dark stain for the doors and drawer fronts was the original, although none of the original can be used without stripping and re-staining.

This is birch veneer- ironed on, stained, and two coats of polyurethane.

This is birch veneer- ironed on, stained, and two coats of polyurethane.